Vat Photo Polymerization

Vat Photo Polymerization

Autor

- Dr.-Ing. Tassilo Moritz

- Winterbergstraße 28, 01277 Dresden, Germany

Telefon +49 351 2553-7747

Fax +49 351 2554-197 - E-Mailtassilo.moritz@ikts.fraunhofer.de

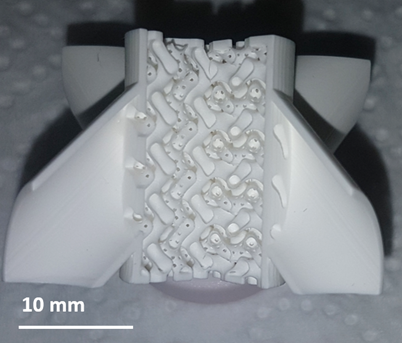

Vat Photo Polymerization (CerAM VPP), also known as Lithography-based Ceramic Manufacturing (LCM) uses a photo curable monomeric suspension of the ceramic powder which is exposed to a defined wavelength for curing a layer of the desired ceramic component. Thus, the building process takes place layer-by-layer with a layer thickness of 5 to 100 µm with a lateral resolution of min. 40 µm which increases the productivity of the process in comparison to conventional stereolithography using dot-wise exposure by a laser beam. The component is built up hanging top down at the building platform. After removal of residual suspension the component is debindered and sintered to final density which is approx. 99.4 % of theoretical density for alumina and > 99.0 % for zirconia. Beside the before mentioned ceramics also nitride ceramics, mixed oxides, hydroxy apatite, traditional porcelain, and glass components can be made by this method. The complexity of ceramic components realizable with this technology are nearly unlimited, so that many new applications can be addressed.

Mixing component for three fluids and flow heater with complex inner structure (Source: Fraunhofer IKTS)

Heating structure applied by aerosol jetting (Source: Fraunhofer IKTS)

-

Webmeeting / Webkonferenz | May 02 - May 2, 2022

Webmeeting / Webkonferenz | May 02 - May 2, 2022

AKK-Frühjahrstagung 2022 -

Ausschuss / Arbeitskreis | Jun 14

Ausschuss / Arbeitskreis | Jun 14

2. Mitgliederversammlung des Anwenderkreises Keramische Additive Fertigung in der DKG (AKF) -

Webmeeting / Webkonferenz | Jun 17

Webmeeting / Webkonferenz | Jun 17

DKG-Hauptversammlung 2022 -

Webmeeting / Webkonferenz | Jun 17

Webmeeting / Webkonferenz | Jun 17

FDKG-Hauptversammlung 2022 mit Vorstandswahl (Wahlperiode 2022-24)